We protect the world’s infrastructure with rope access technology.

The origin of rope access technology is not rock climbing but SRT (Single Rope Techniques), which was developed from caving exploration techniques.

In Western countries, the construction industry was quick to adopt and develop technologies based on SRT. Today, international organizations such as IRATA (International Rope Access Trade Association) and SPRAT (Society of Professional Rope Access Technicians) have established industry standards for rope access work.

In Japan, Keystone Inc. led the development of rope access technology in the 1990s, evolving it into a method specifically applied to infrastructure inspections, surveys, and repair work.

“3D Rope Access Technology [SORAT]” is a unique rope access technique developed by Keystone Inc. in the late 1990s.

Unlike conventional methods that primarily focus on vertical movement, Keystone’s innovation, known as “3D Rope Access Technology”, allows unrestricted movement in all directions—up, down, left, right, forward, and backward. This advancement enables safe access to difficult locations, such as the underside of bridges, where traditional methods have been challenging. As a result, it has made more advanced and precise operations possible.

Originally developed for infrastructure inspection and surveying, this technology is now widely used in repair work and various construction sites. It is recognized as the industry’s leading method for ensuring safe and efficient access to high and hard-to-reach locations. Our association is dedicated to promoting and expanding the use of this cutting-edge technology worldwide.

The name “SORAT” originates from the acronym of the Society Of Rope Access Techniques, the organization responsible for managing and promoting this technology.

It is pronounced “SORAT” (so-rat).

Technical Name

Rope Access Technology [SORAT]

Technical Abbreviation

[SORAT] or [SORAT] Technology

Developer

Keystone Co., Ltd.

Development Period

Late 1990s (Technology continues to evolve)

Technical Management

Society Of Rope Access Techniques (SORAT)

(Training & Certification, Technical Manual Publication)

Technical Features

• Free three-dimensional movement, ensuring safety, speed, and reliability

•Accident-free record since its development

• Complies with the Revised Occupational Safety and Health Regulations (Lifeline)

• Recognized as a designated technology in the Bridge Inspection Guidelines (MLIT, Japan)

Safety Assurance Technology

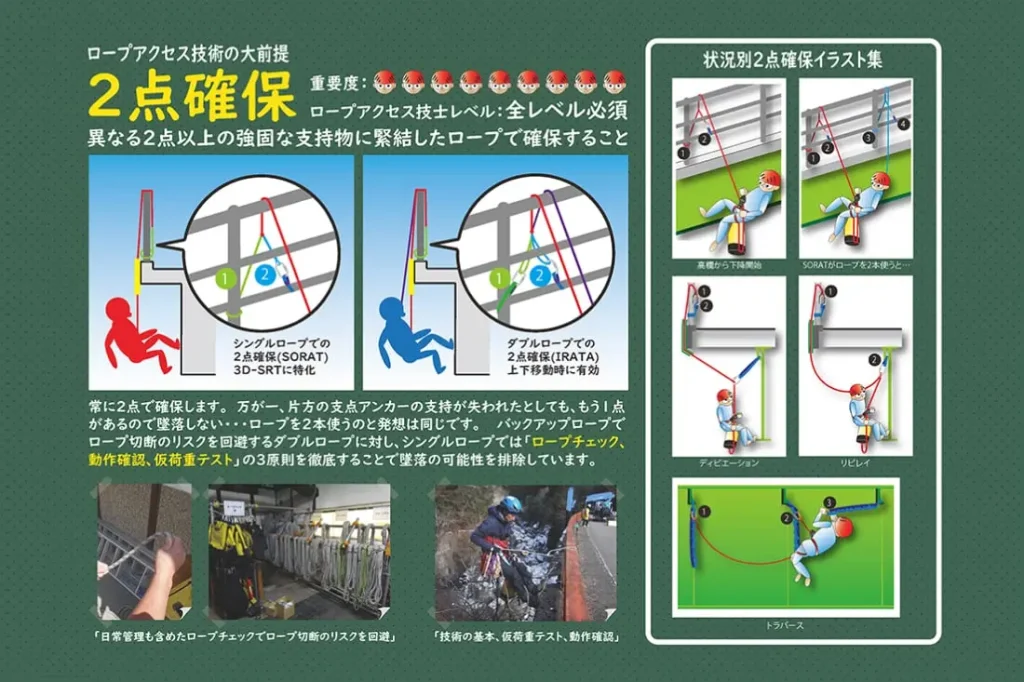

•“Two-Point Safety” as the fundamental principle

• Load tests, motion checks, and rope inspections, among other safety measures

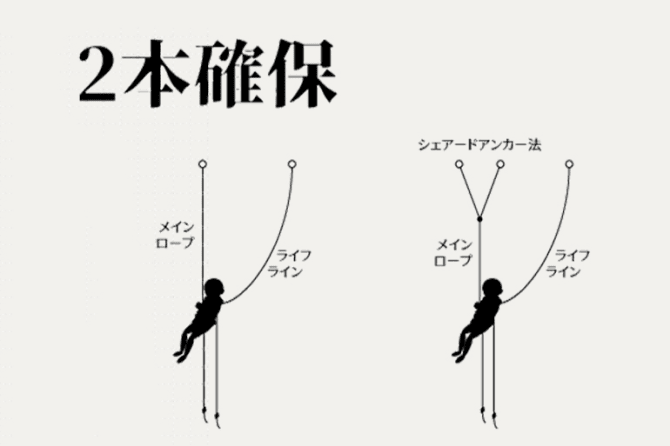

A lifeline refers to a secondary rope used in rope access work to ensure safety.

It is typically installed parallel to the main rope and serves as a backup in case the main rope is severed or damaged. The use of lifelines is mandatory for rope access work worldwide.

In Japan, the Revised Occupational Safety and Health Regulations (2016) officially defined “rope access work” and made the use of lifelines mandatory in such operations.

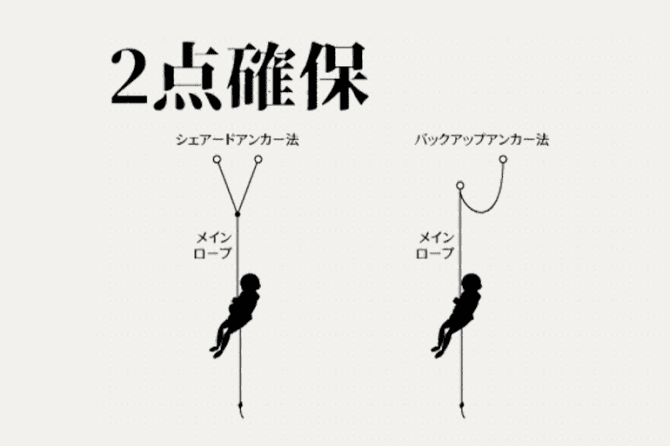

In standard rope access operations using a lifeline, the “Two-Rope System” is the common safety approach.

This method involves using both a main rope and a lifeline to support the worker’s weight, which limits movement primarily to vertical directions (up and down).

On the other hand, Keystone Inc. developed the 3D Rope Access Technology [SORAT], which adopts a “Two-Point Safety” system.

In Two-Point Safety, the worker is supported by at least two anchor points, ensuring a secure attachment to the structure.

This approach enables free three-dimensional movement—not only up and down but also left, right, forward, and backward—allowing for safe and highly efficient operations in complex environments.

[SORAT] technology is a safety-compliant method developed based on the Revised Occupational Safety and Health Regulations (2016). It is also recognized in the Bridge Inspection Guidelines by Japan’s Ministry of Land, Infrastructure, Transport, and Tourism (MLIT), making it an essential technology for infrastructure inspection.

Unlike conventional rope access methods that require a lifeline, SORAT technology ensures an equal or higher level of safety without using a lifeline. According to the safety regulations, the requirement to install a lifeline is waived for “survey, inspection, and testing operations” under the following conditions:

Lifeline Installation Exemption Conditions

1. The main rope must be secured to at least two separate, robust anchor points.

2.Additional safety measures, such as deviation and re-belay, must be implemented to avoid areas where the main rope could be at risk of cutting or damage.

This exemption was established due to the critical role of SORAT in diagnosing aging infrastructure and its ability to enable three-dimensional movement in complex field operations, proving that SORAT surpasses conventional lifeline-based safety methods.

The core concept of “Two-Point Safety” is to always support the worker with at least two anchor points. This ensures that even if one anchor point fails, the remaining point will prevent a fall.

This mechanism guarantees safety without the need for a lifeline.

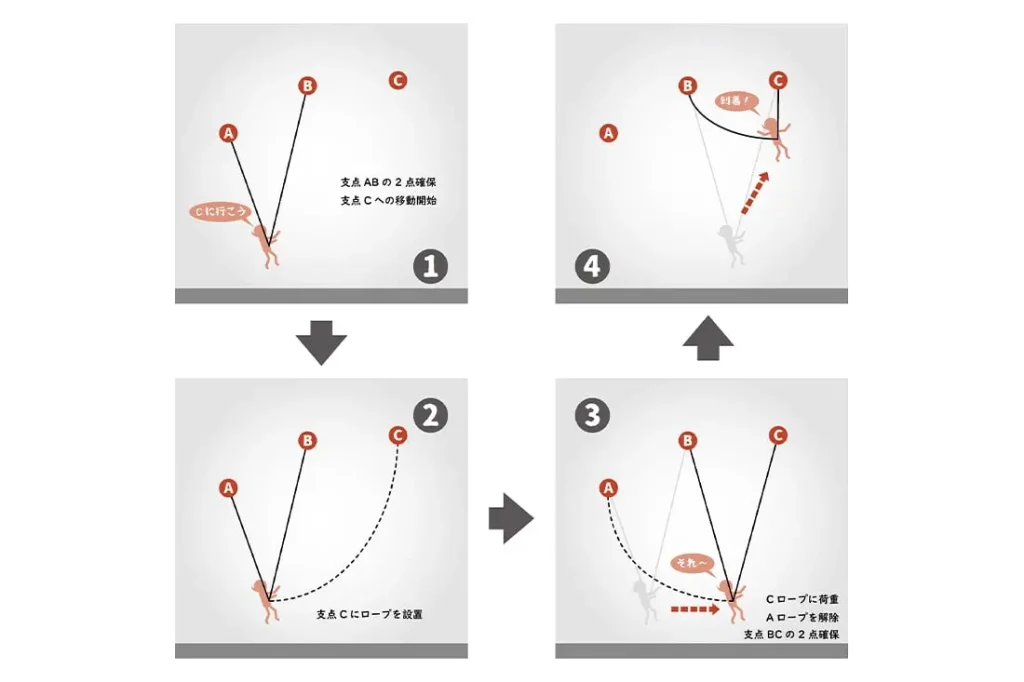

SORAT technology, which adopts the “Two-Point Safety” system, goes beyond the conventional “Two-Rope System”, which limits movement to only vertical directions. Through the following process, workers can maintain safety while moving freely in three dimensions:

1.The worker is initially secured to two anchor points (A and B) using the “Two-Point Safety” method.

2.A new anchor point (C) is established for movement, temporarily creating a “Three-Point Safety” system.

3.The load is transferred to the new anchor point (C), and support from the original point (A) is released.

4. By repeating this process, free and safe movement in all directions—up, down, left, right, forward, and backward—is achieved.

✅ Enables three-dimensional movement in all directions

✅ Ensures a safe working environment without requiring a lifeline

✅ Ideal for inspection, surveying, and construction work in high and difficult locations

✅ A safety-compliant method recognized in the Revised Occupational Safety and Health Regulations and MLIT Bridge Inspection Guidelines

With these benefits, SORAT represents a groundbreaking rope access technology that expands new possibilities for high-altitude operations.